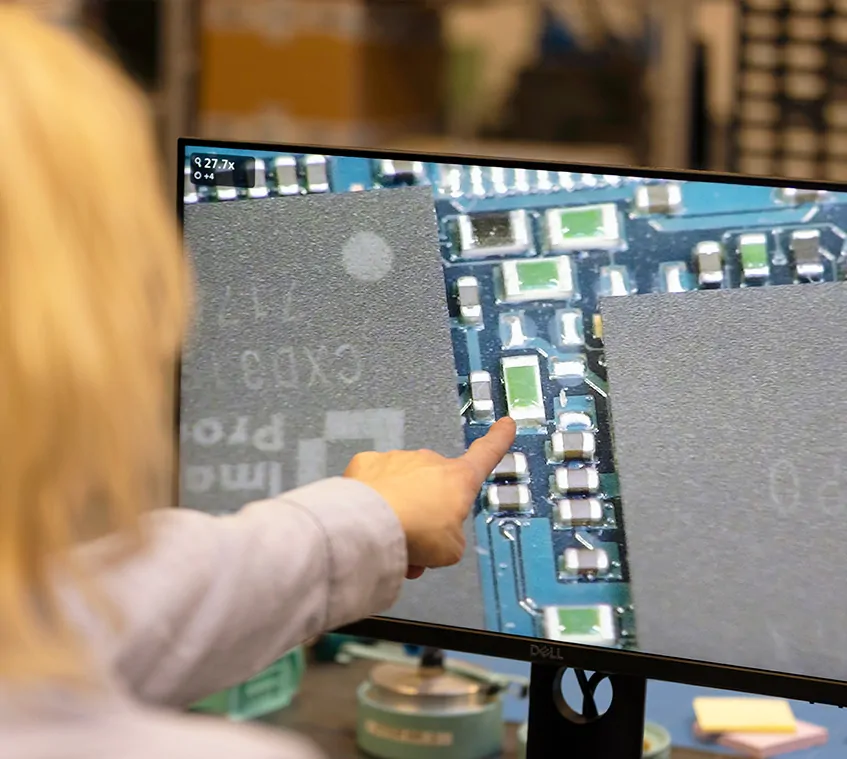

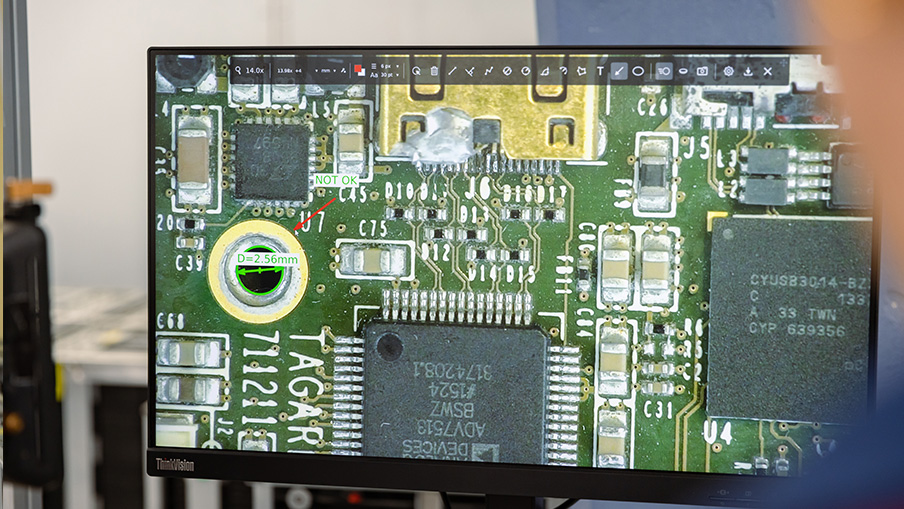

For businesses doing visual inspections in order to uphold the highest standards of quality and reliability, precision isn’t just a luxury – it’s a necessity. For these processes, inspection microscopes have emerged as indispensable tools.

In this blog post, we delve into eight specific benefits of using inspection microscopes in professional settings and articulate why incorporating a digital version of these devices is pivotal for businesses aiming to excel in their respective industries.

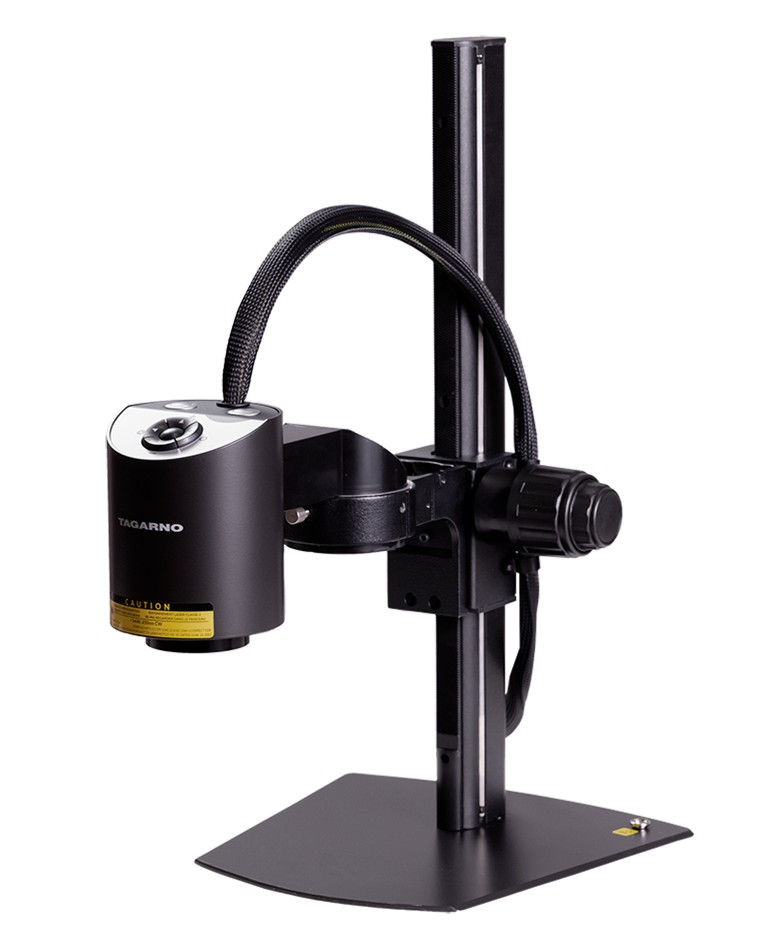

Let’s start by specifying what an inspection microscope is, who uses them, and the different types of inspection microscopes you can choose from.