Magnification has been an integrated and crucial part of PCB production and rework for many years.

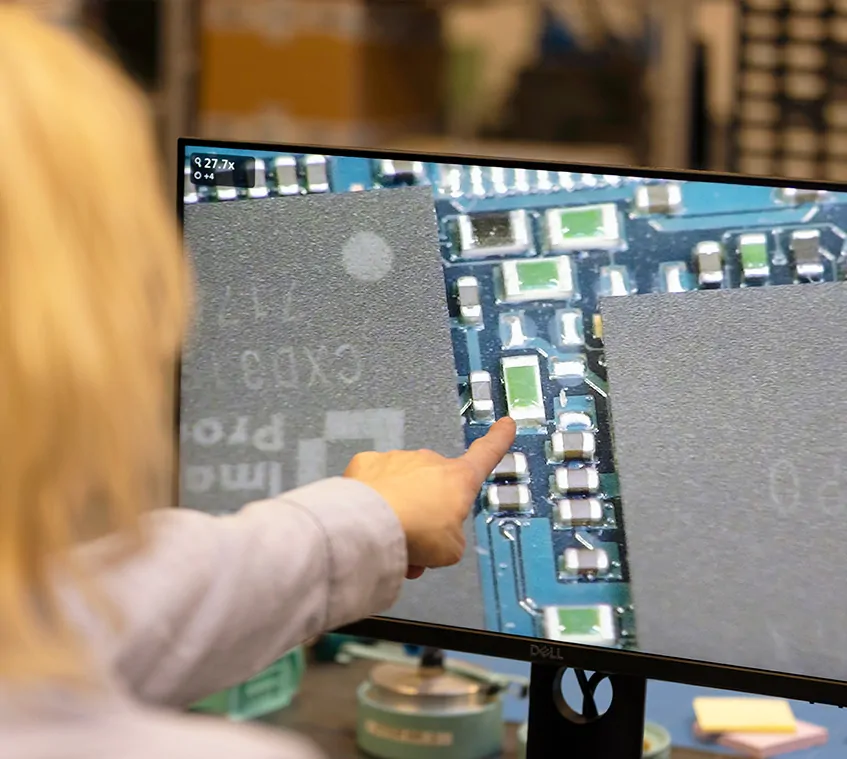

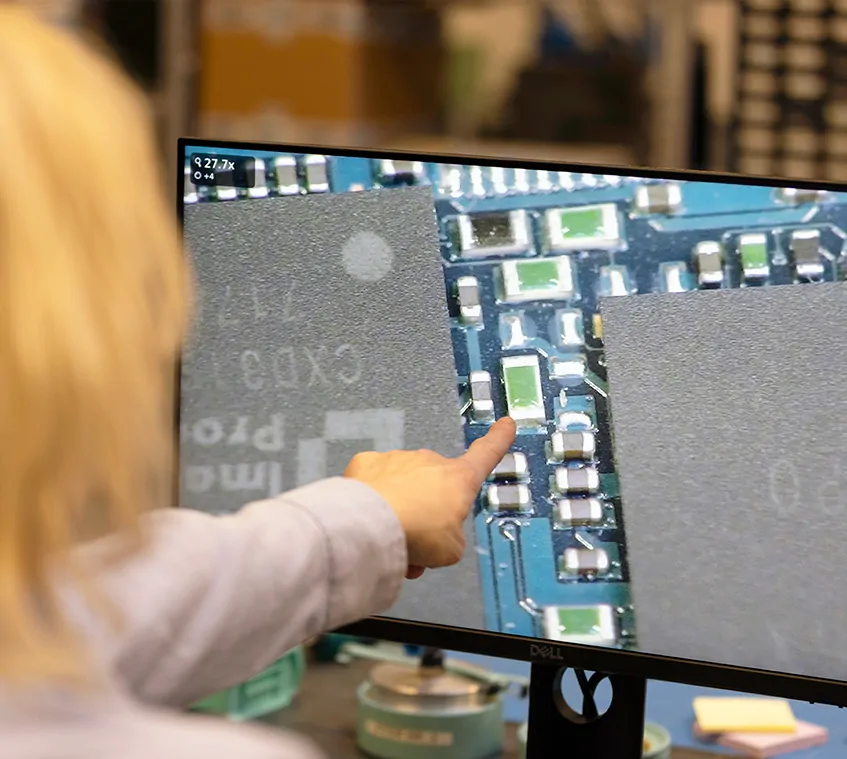

What many Electronics professionals find today, however, is that traditional magnification systems can no longer provide the required magnification levels when doing PCB inspection control or reworking faulty PCBs – nor are they equipped to capture photos and create documentation of your work in an efficient way. This sends PCB manufacturers hunting for new equipment that can do the job.

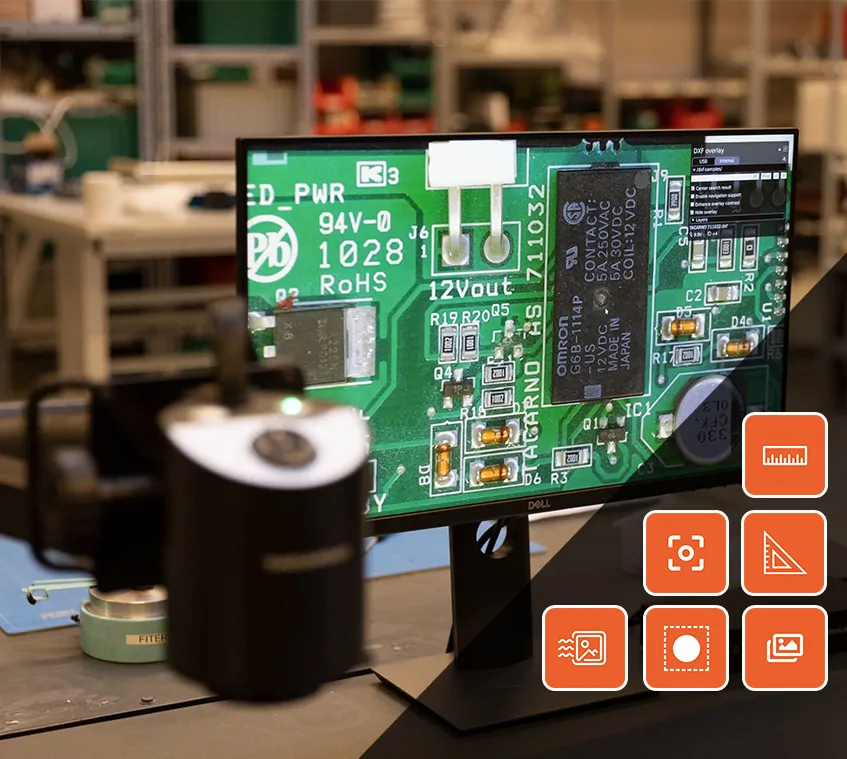

If that sounds familiar or if you’re simply curious about how to use a digital microscope for soldering and PCB inspection, this guide is the right place for you.