BENEFIT 1:

See every little details thanks to excellent image quality

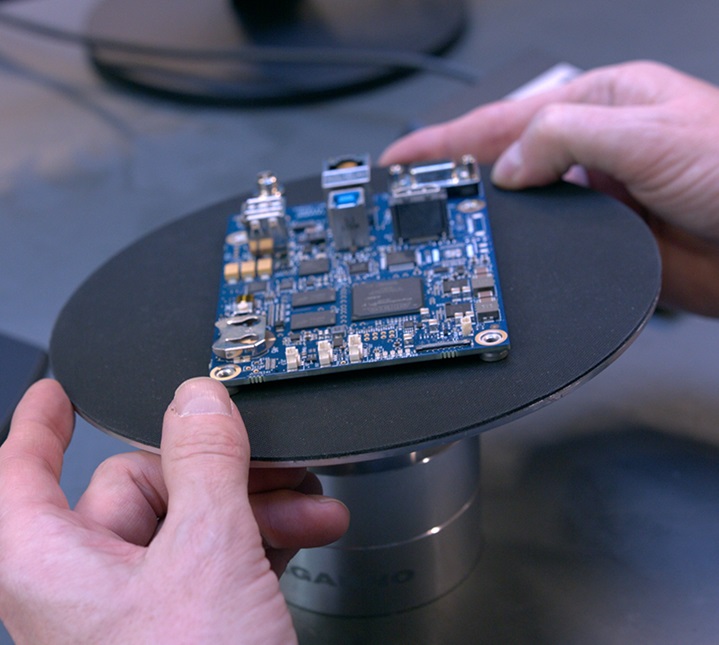

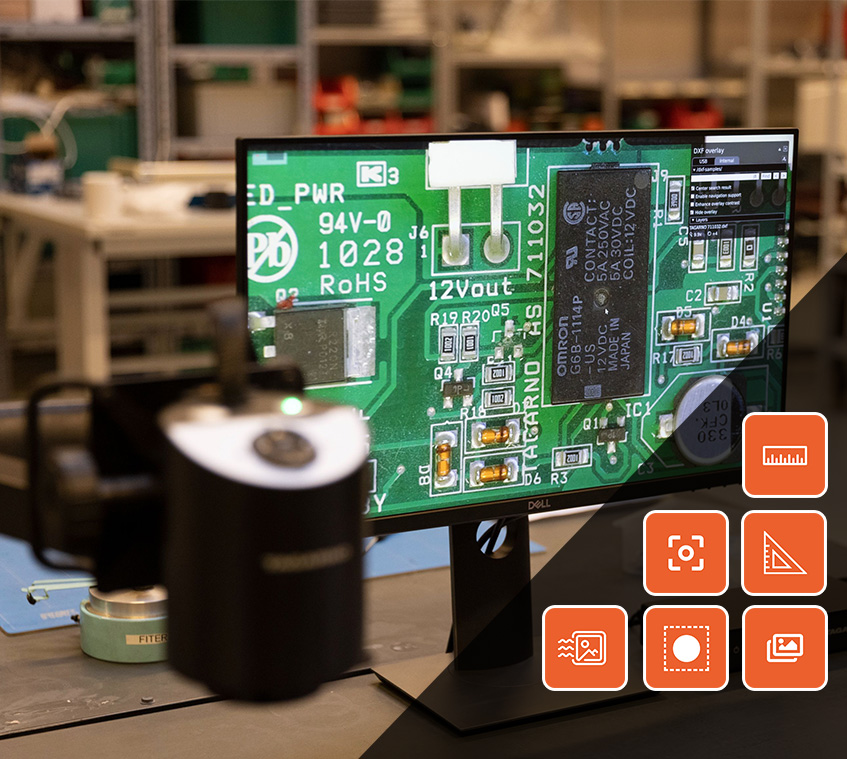

When choosing a digital microscope for PCB inspection, it’s important to know how your choice of camera within the microscope affects not only the image quality but also the user experience. Because while it may be tempting to look for a microscope with high magnification capabilities, it’s important to know that high magnificaiton capabilities doesn’t automatically guarantee great image quality.

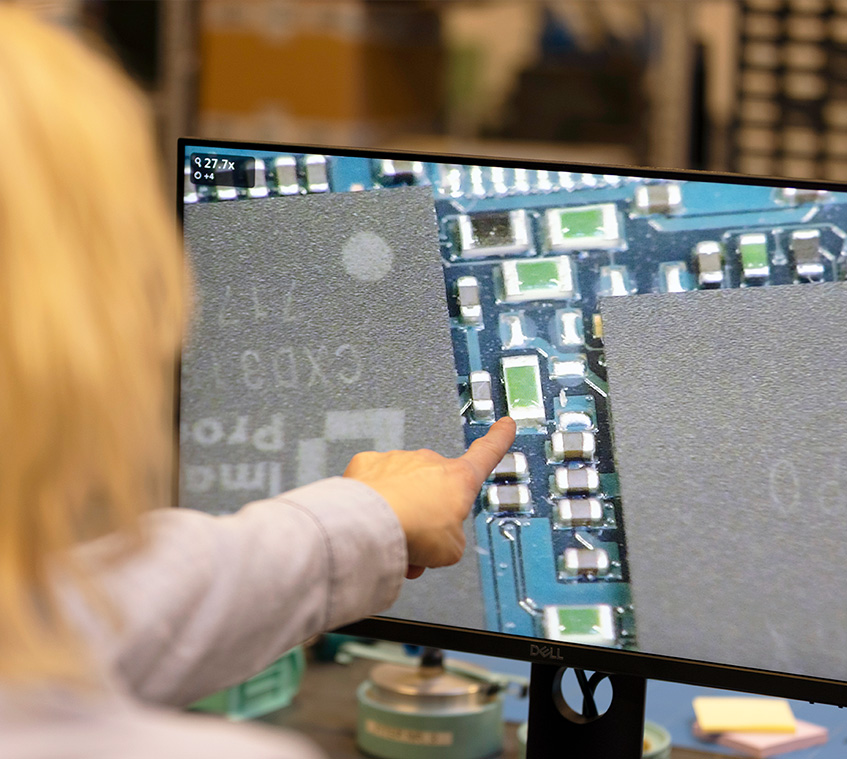

For that reason, keep your eyes out for a microscope with 1080p image quality (FULL HD) and 30x optical zoom. This will result in extremely sharp images that will show all details of your sample, even at 660x magnification.

It’s also important to check the framerate of the microscope. With 60 frames per second and progressive scan, you won’t experience any delay or distortion as you’re moving the sample around under the microscope. While this may not sound important, you’ll quickly notice the difference if you’re working with lower frame rates or even interlaced scan rather than progressive scan if you need to manipulate the sample under the microscope.