Conclusion

Selecting the right digital inspection system requires understanding your specific needs and evaluating the right tools that meet those demands. While automated systems such as AOI machines serve well in high-volume production environments like electronics manufacturing, TAGARNO specializes in manual inspection systems that provide unmatched flexibility and detail across industries.

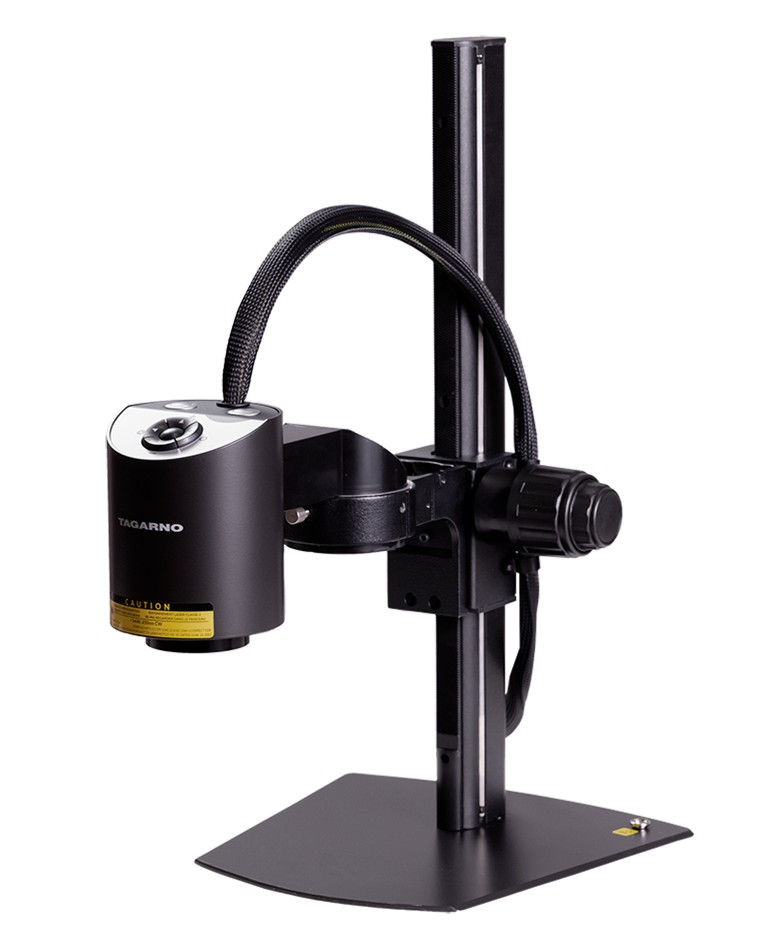

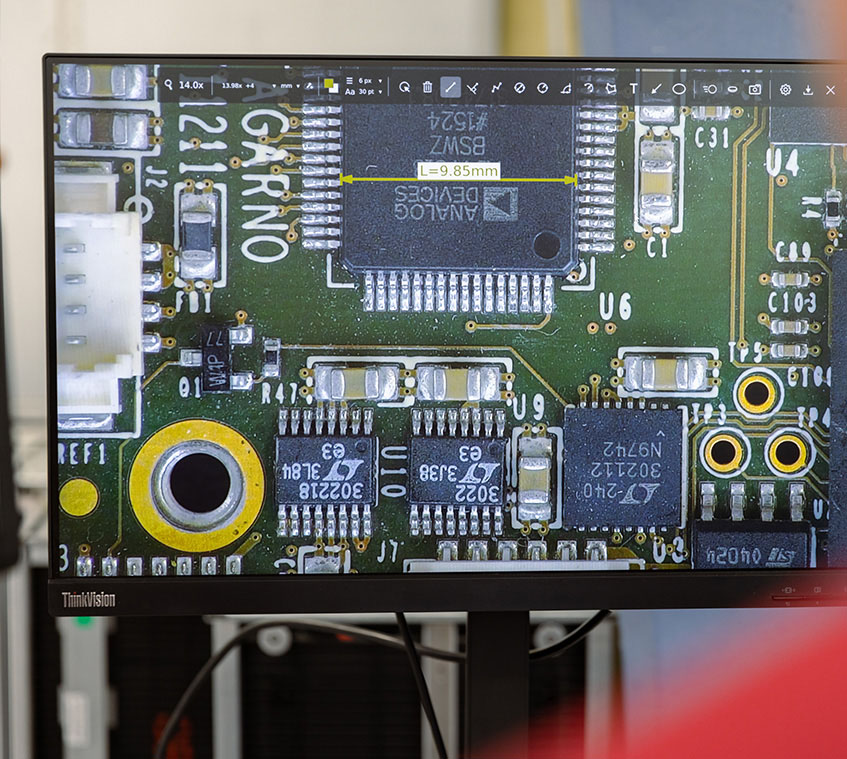

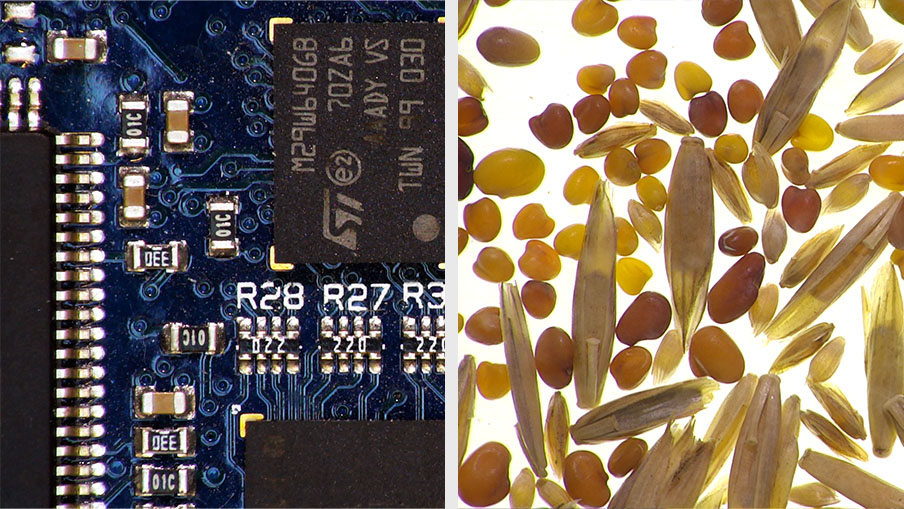

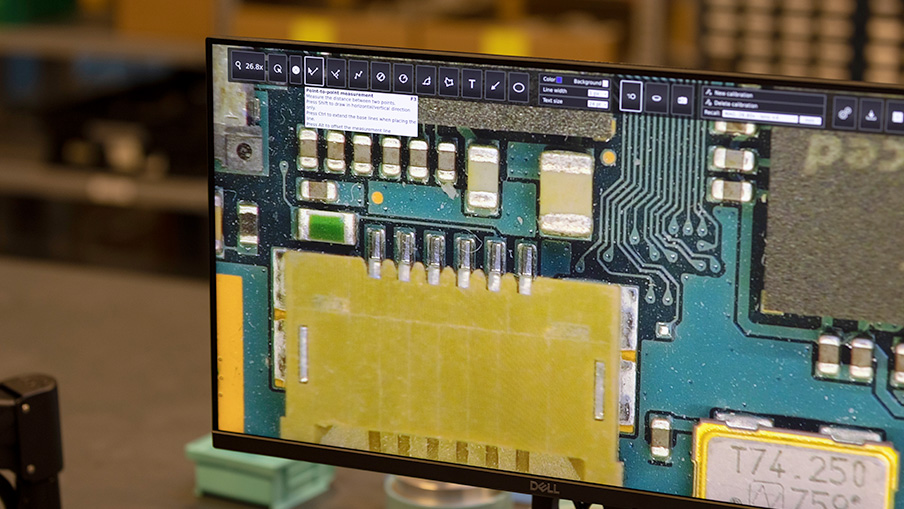

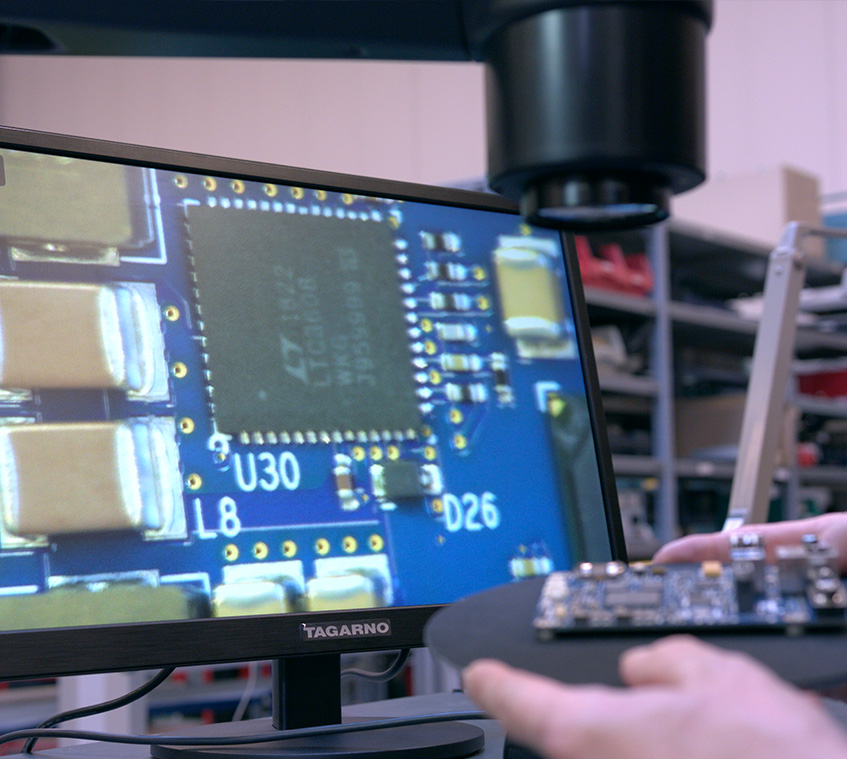

TAGARNO’s range of digital microscopes, including the cost-effective TAGARNO ZIP, the advanced TAGARNO TREND, and the 4K TAGARNO T50, offers superior precision and adaptability across various industries from electronics to agriculture and material sciences. These systems ensure that you can conduct thorough and meticulous inspections, crucial for quality control and research and development efforts.

By choosing TAGARNO, you benefit from digital inspection systems that not only enhance the quality and efficiency of your operations but also fit seamlessly into your workflow, providing detailed insights and reliable performance. Explore how TAGARNO can transform your inspection processes and help you maintain the highest standards of accuracy and efficiency in your industry.