In conclusion

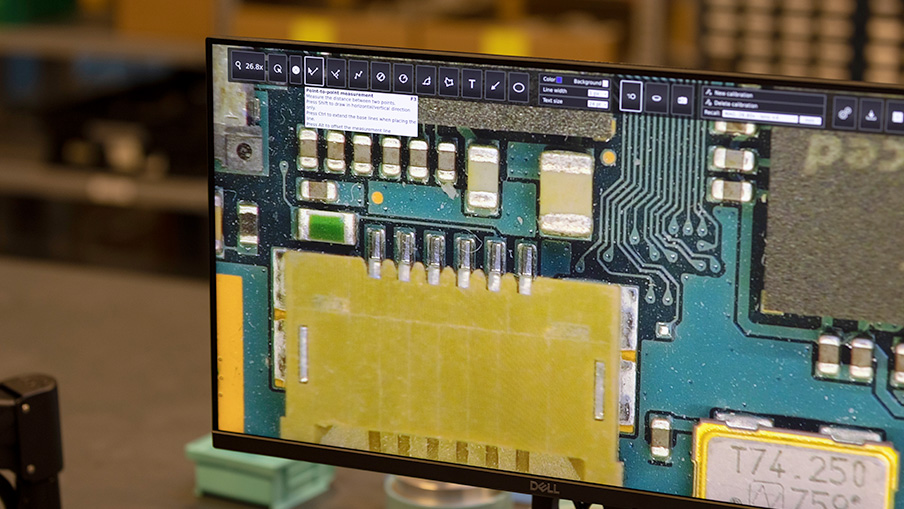

Choosing the right inspection tool is crucial for maintaining the high standards required in the electronics industry. Camera microscopes offer significant advantages over traditional magnifying tools, from a broader magnification range and advanced features and software capabilities to enhanced documentation and user-friendliness. Whether you opt to retrofit your existing microscope with a camera or invest in a state-of-the-art digital microscope, the benefits to your quality control and rework processes will be immediate and profound.

However, choosing a digital microscope with a built-in camera offers unmatched benefits by being designed to maximize the advantages of digital imaging technology.

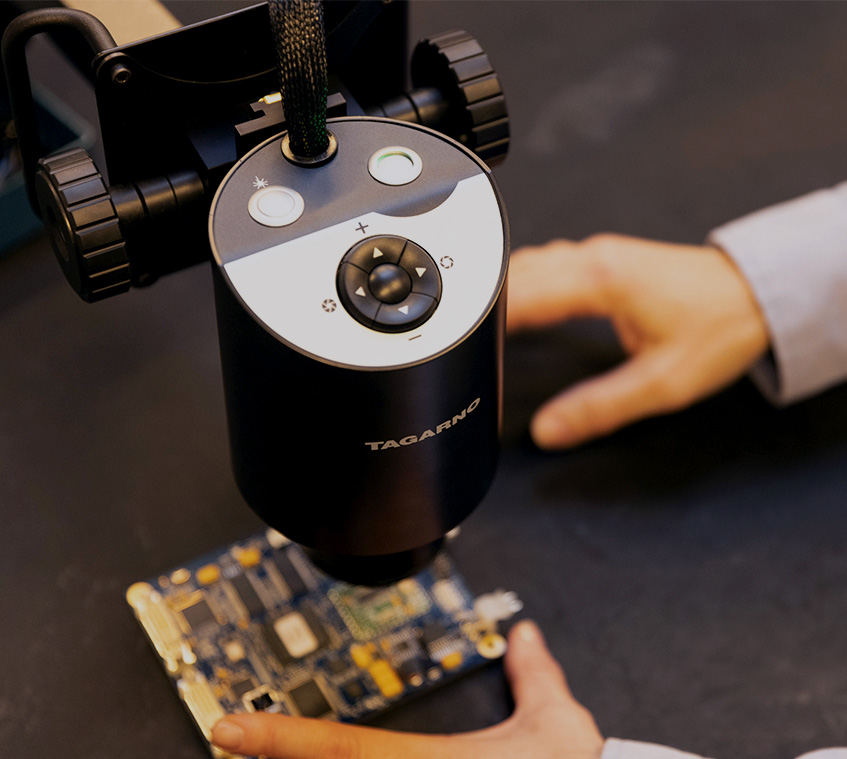

A digital microscope with an integrated camera also enhances operational efficiency through features like real-time analysis, easy documentation, and improved collaboration tools. The ergonomic design and user-friendly interface reduce training time and minimize physical strain, boosting productivity and safeguarding worker health.

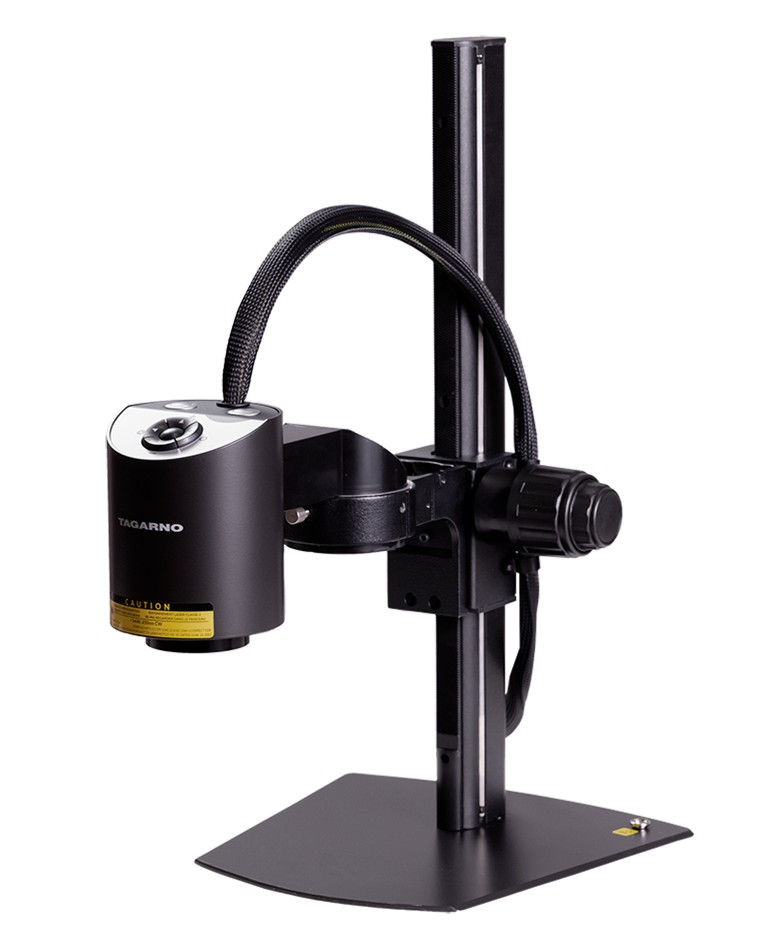

Camera microscope options available from TAGARNO

At TAGARNO, we specialize in state-of-the-art digital microscopes that are built from the ground up with integrated cameras. We focus exclusively on these complete solutions rather than offering camera add-ons to existing microscopes. This specialization ensures that our products are optimized for the most demanding tasks in electronics manufacturing, providing our customers with a tool that is not just fit for purpose but also future-proof, aligning with the evolving needs of the industry.

You can explore the camera microscopes available from TAGARNO via our configurator. Simply click the button below.