The Importance of Real-Time 4K in Digital Microscopy

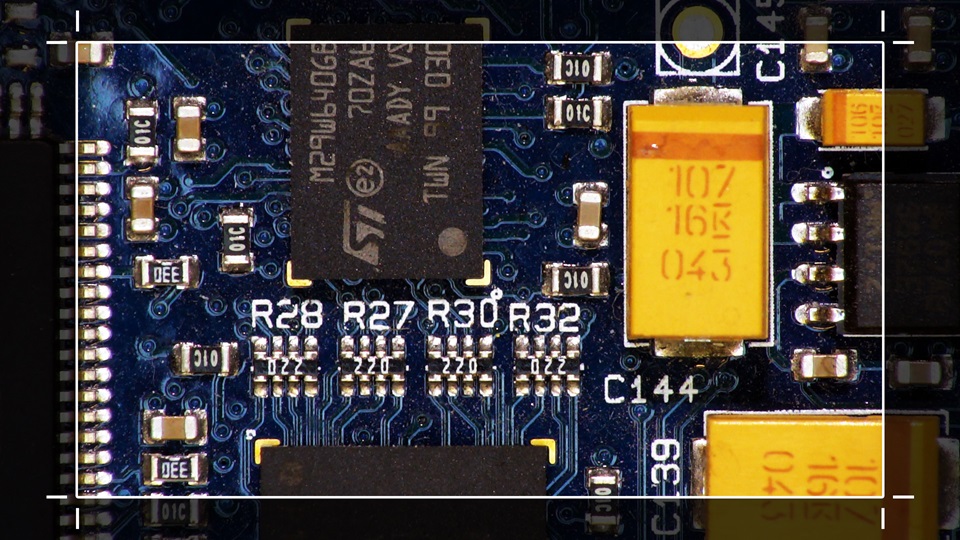

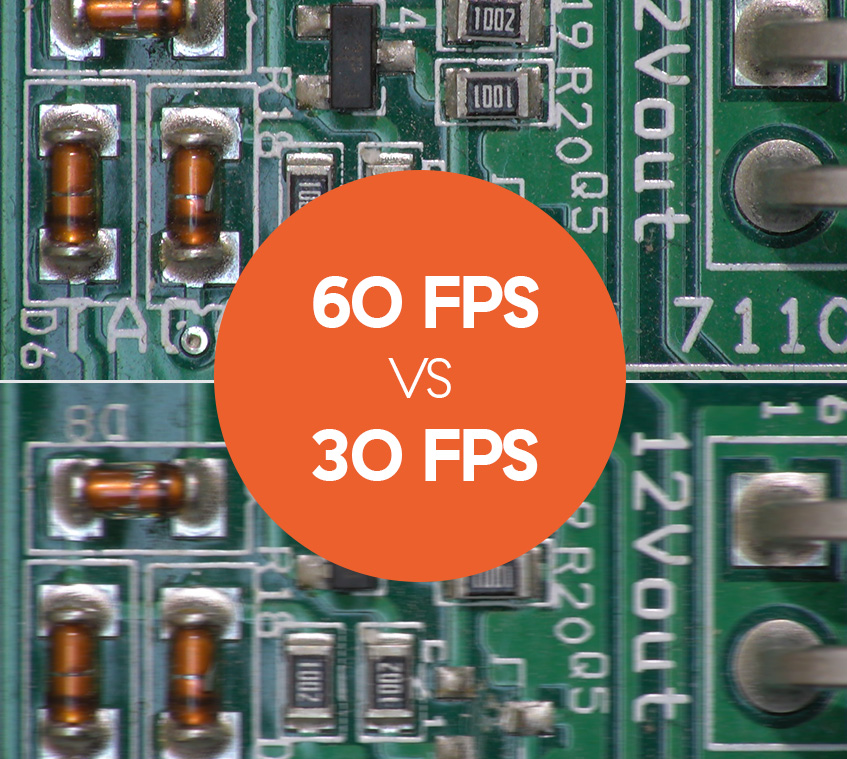

In the realm of electronics manufacturing, the ability to quickly observe and document minute details on components such as printed circuit boards (PCBs) is essential. A 4K digital microscope provides a resolution of approximately 3840 x 2160 pixels, offering four times the digital resolution of standard 1080p. This high resolution enables technicians to see and document finer details, particularly at lower magnifications, with greater clarity, which is crucial for identifying defects and ensuring high-quality production.

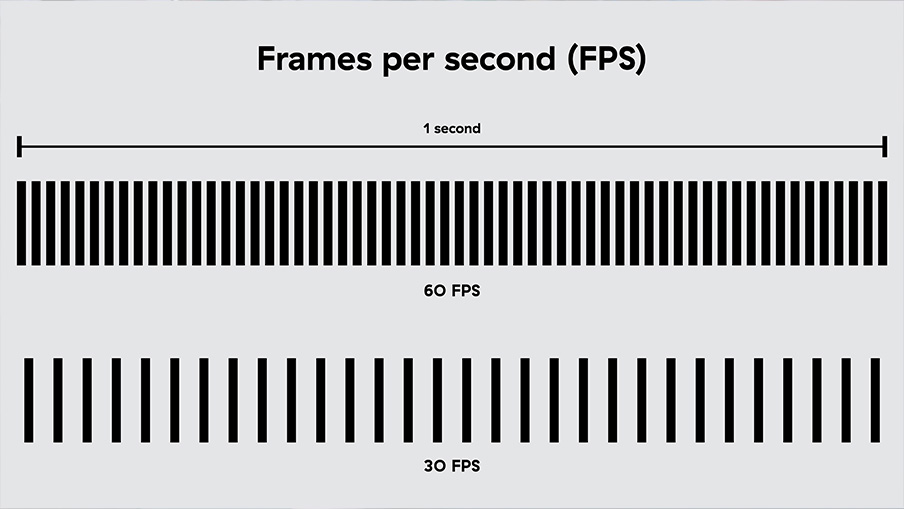

A digital microscope, however, is not just a static image, but has an image that must keep pace with the constant motion that is seen in practical inspections. A significant challenge has remained on usable frame rates, with real-time, low latency, 4K imaging. Because a 4K sensor has four times the pixels, it also has four times the data throughput, which presents an engineering challenge for generating fast frame rates. While 4K systems have been able to record at 60 FPS for years, displaying low-latency live images has generally been limited.

Traditionally, most 4K systems’ live views have been limited to 25-30 FPS due to the dramatic increase in data handling coming off the sensor. For a digital microscope that does not have eyepieces, 60 FPS is very important. Higher frame rates translate to smoother live “real” images, reducing motion blur and providing a more natural view of moving parts under the microscope. Low latency is also important because input-output delay can lead to a negative feedback effect. A 60 FPS with near-zero latency feature is particularly beneficial during dynamic or manual processes such as soldering and component placement, where observing real-time movements is necessary.