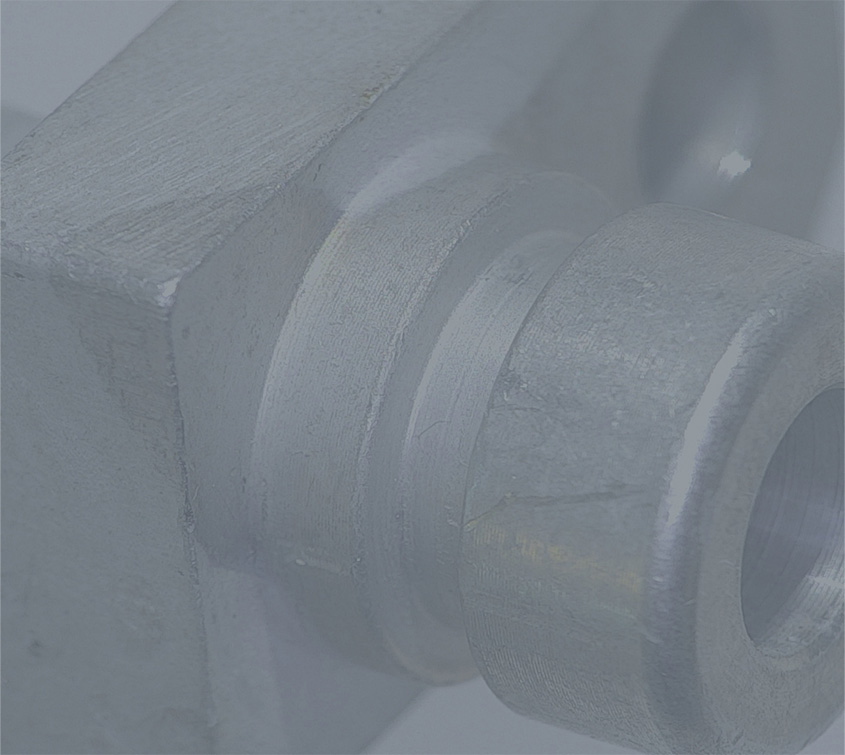

Shape, color and surface inspections of metal parts

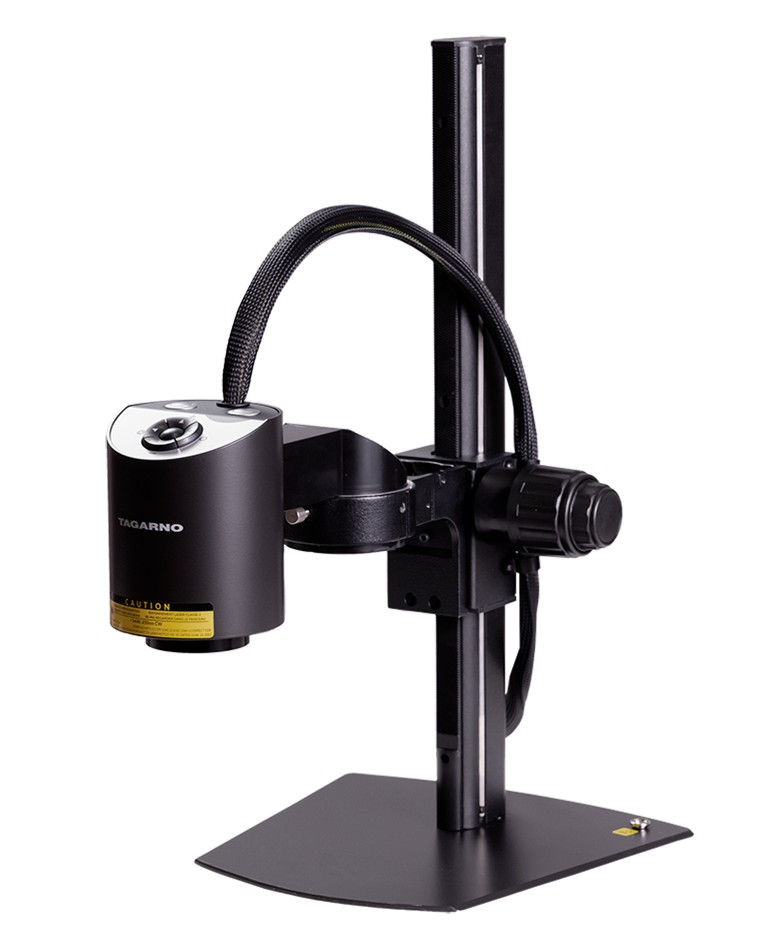

Doing metal inspections to verify the quality of your products is a time consuming and demanding task. For this process, you not only need a metallurgical microscope that produces crystal clear images that enables you to spot any burrs, flashes, chips, etc. You also need a comfortable setup with proper ergonomics to avoid operator fatigue and minimize escape rates. This is where a digital microscope comes in.

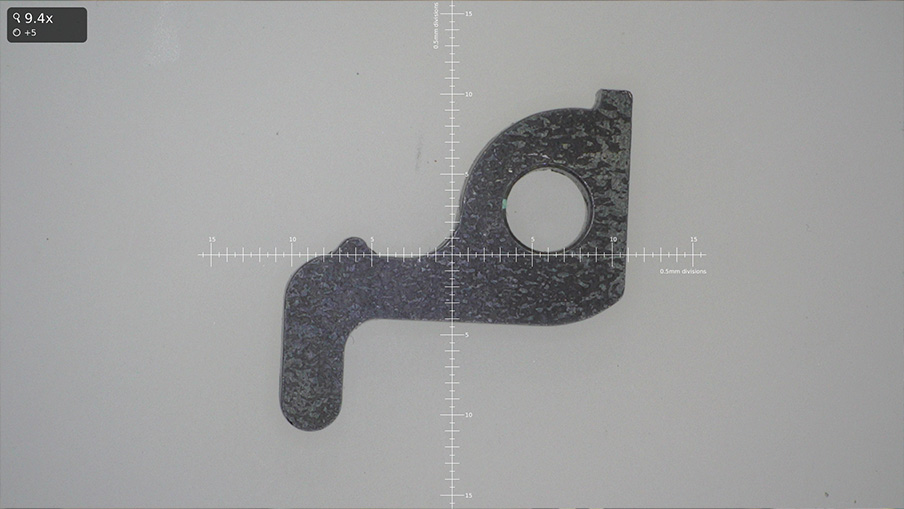

Use the bestselling Measurement app to measure the size of your findings, either manually or with the help of heads-up displays. Then, document your findings and adjust your production accordingly if needed.

You can also use the Image comparison app to compare current samples to reference photos of defects to guide operators on what to look out for.