Medical device manufacturer

Consistency and improved efficiency

This company had one goal in mind. Consistency and efficiency. By using their microscope smartly, they achieved their goal and can perform higher quality inspections.

Boosting the

Consistency and efficiency

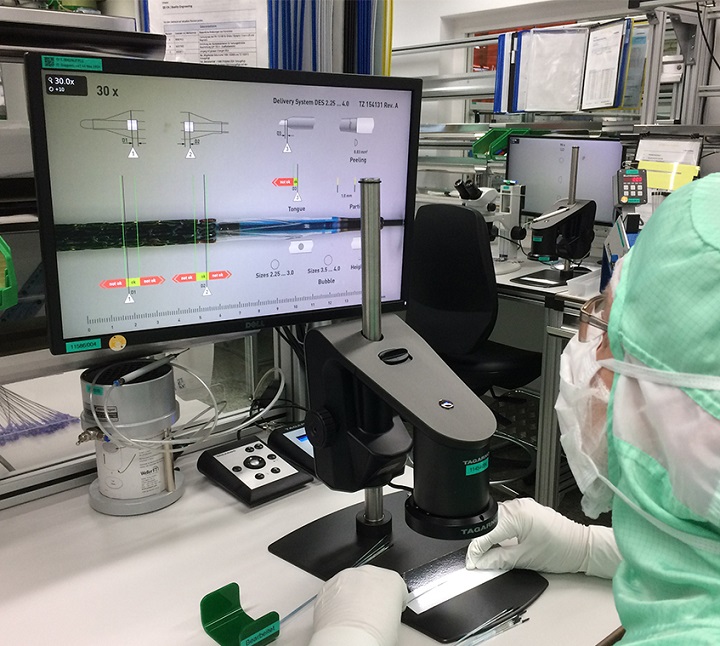

A leading medical device manufacturer invested in 22 microscopes to have more consistency and efficiency in their inspections. And the investment paid off.

Today, the company with production facilities in Germany and Switzerland can prepare samples 5 times faster than before and are using the correct settings every single time.

Before upgrading, operators had to manually change settings between inspections. This was time consuming and no one could be sure that the correct settings were being used. On top of that, verifying products was a manual process with a ruler.

Today, the preset feature makes sure that the same settings are used again and again. And instead of spending time adjusting the settings manually, the microscope does it automatically.

Lastly, with the PNG reference app, the operators can recall a customized graphic to verify the size of their products. The graphic is placed on top of the live image, eliminating the need for manual measurements and creating more efficient and accurate processes.

Our operators love using their TAGARNOs. They are really easy and comfortable to use

Benefits and features

Having an ergonomically correct setup also creates a healthier work environment. With a TAGARNO, the operator can inspect their product on a monitor.

This eliminates straining and awkward work postures and prevents eye strain as well as neck, back and shoulder pain. Something that 80 % of microscope operators usually suffer from.

Explore

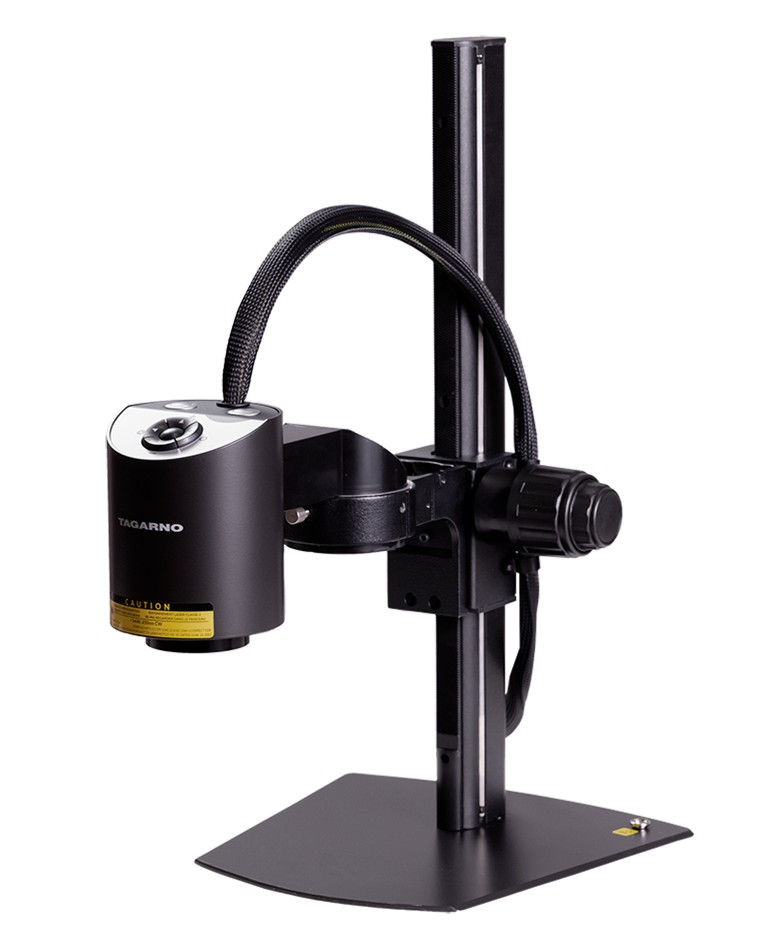

Our Digital microscopes

Smart on the outside, adaptable on the inside

TAGARNO digital microscopes give you unique and easy to use magnification equipment to use in a variety of quality control processes in an endless range of segments.

See all products

Fill out the form below to get in contact with the TAGARNO sales team. If you have a support question, please visit our Support page.

You are also welcome to contact a person from the TAGARNO sales team directly