What are the benefits of using a digital microscope measurement software?

The most common reason for choosing a digital microscope measurement software is to eliminate manual measurements, e.g. with calipers. When measuring manually, an operator typically needs to manually note the measurement on a piece of paper or type it into a Data management system. This can be a lengthy process and the accuracy of the measurements will greatly depend on the individual operator and their thoroughness.

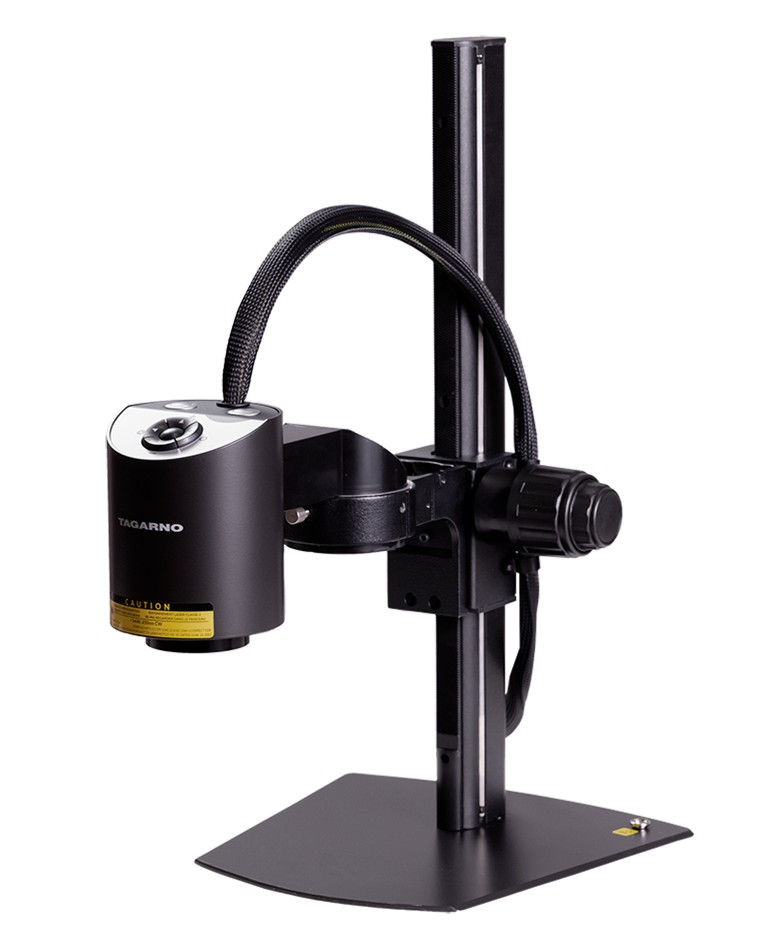

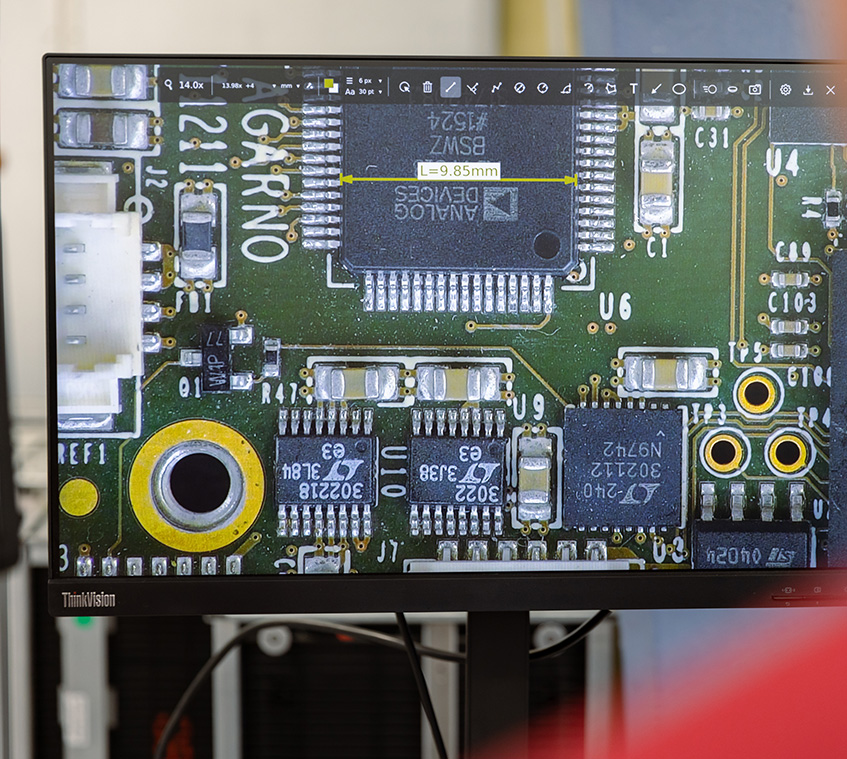

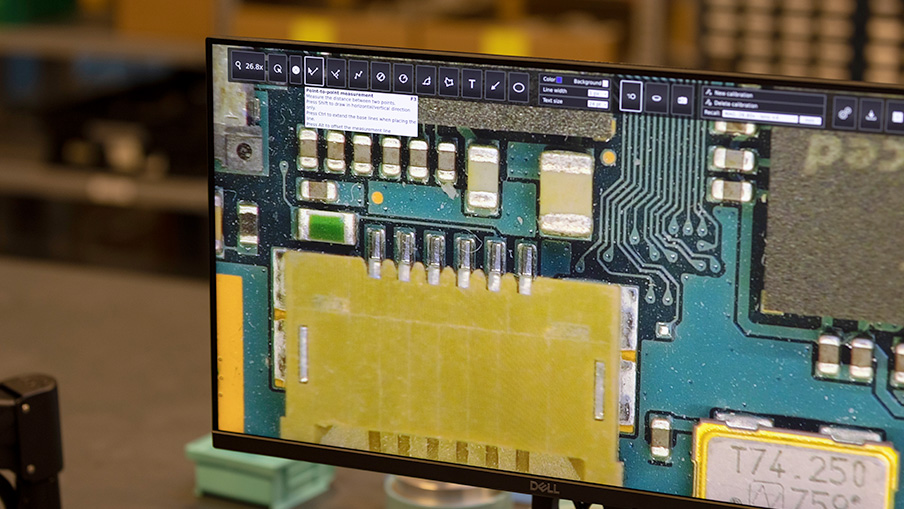

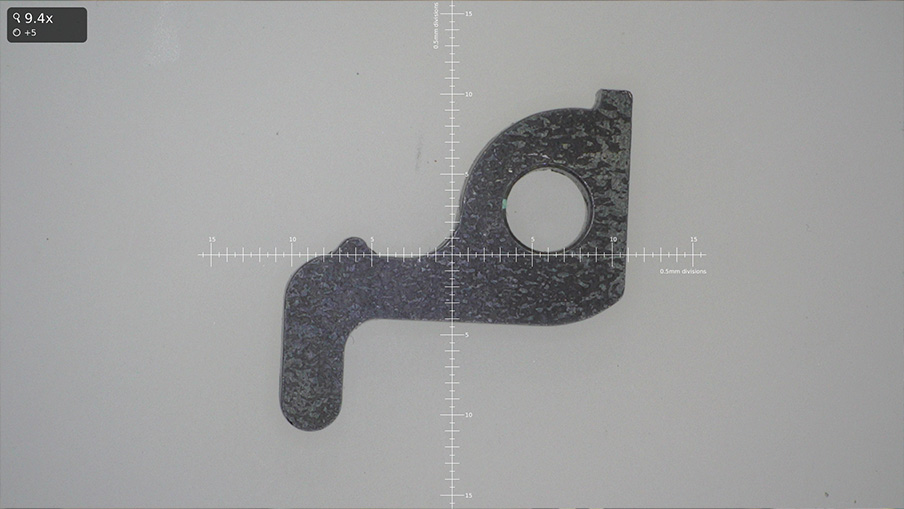

With digital microscope measurement software, however, the measurement is done on a live or still image from the microscope and a photo of the completed measurement can easily be captured.

Key benefits of using a digital microscope measurement software thus include:

- Increased efficiency and accuracy of measurements

- Easy documentation processes and increased traceability

You will be able to reap additional benefits depending on how advanced the digital microscope measurement software that you choose is and what your starting point is. For that reason, let’s have a look at what you need to consider when choosing your next digital microscope measurement software and what benefits you can expect depending on what you choose.